News – current information

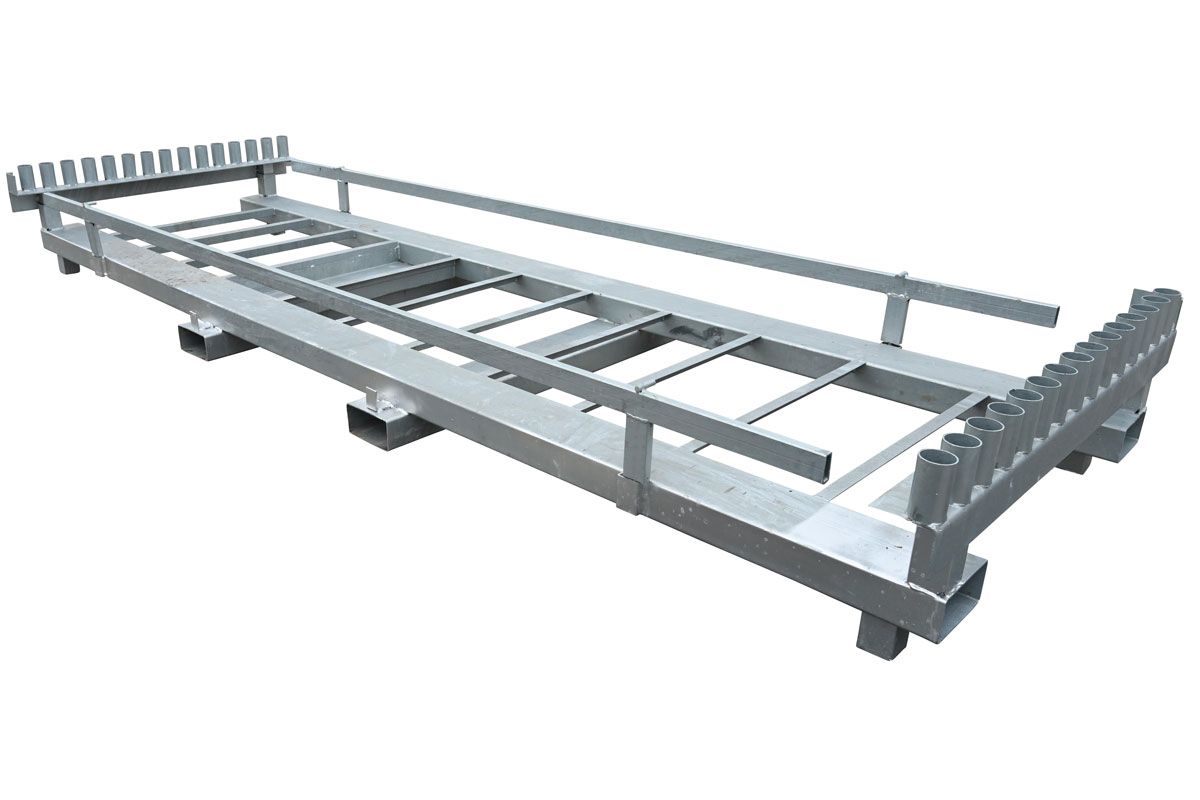

NEW – 10059.7 – Universal plate

22.02.2021

Absolute novelty:

Universal pallet UP 30 for 30 fields and 30 feet in one system

View photos enlarged> click on the picture

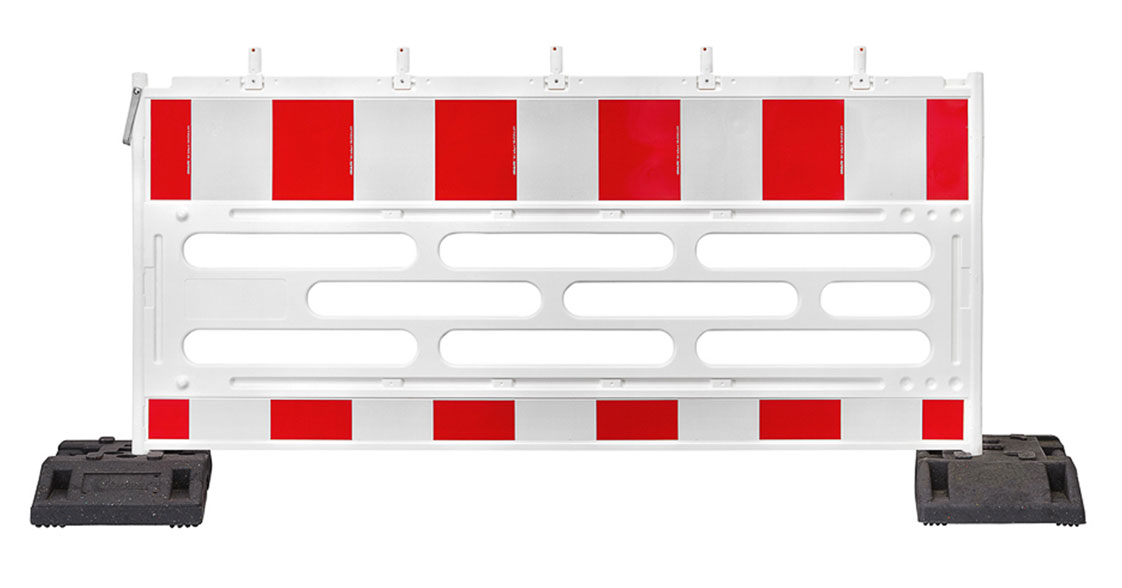

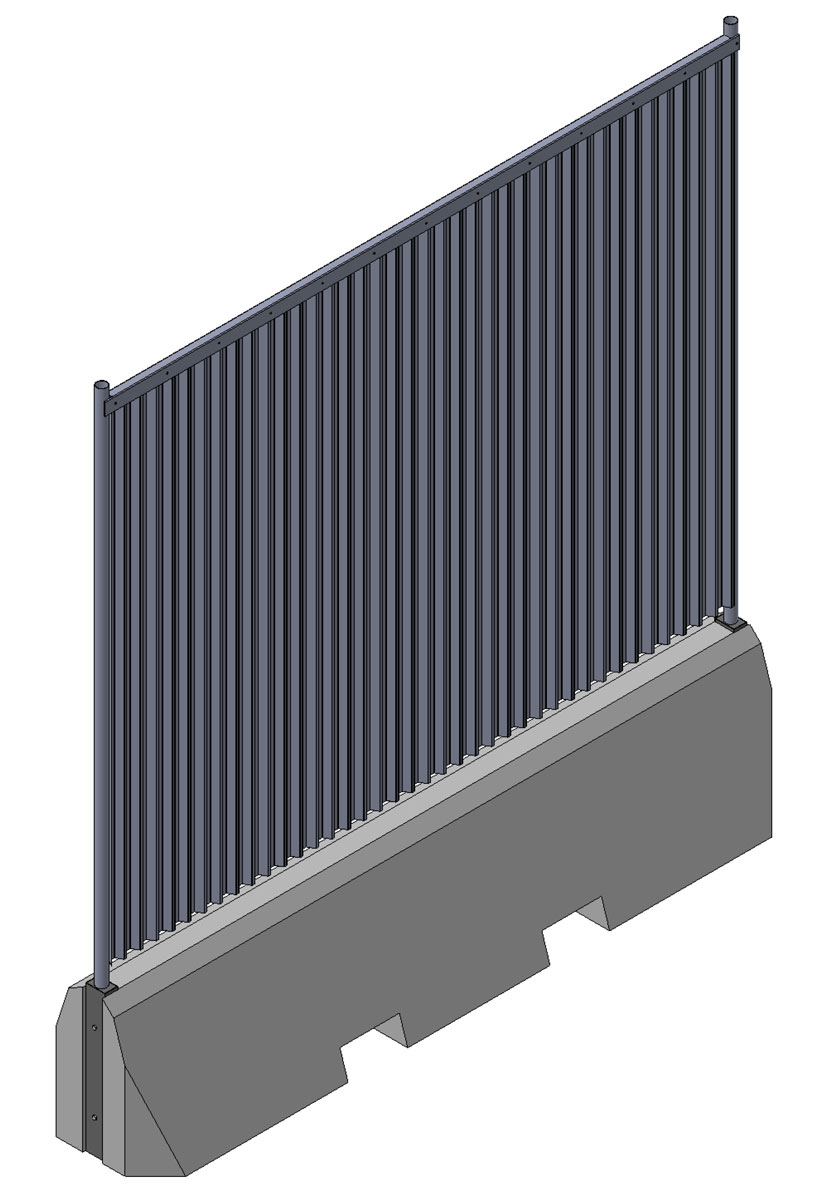

NEU – 10080 – plastic barrier

22.02.2021

Actual new in our programm is teh plactic barrier out of high qualitiy plastic, Oraclite foil 5431 RQ1 and 5831 RA 2 , produced in EU, weight 12 kg

View drawing enlarged > click on the picture

NEW – 10075.3 – mobile fence business

04/18/2020

3,50 x 2,00 with 3 horizontal tubes, hot dipped galvanized code 10075.3

Also available in version economy, galvanized code 10069.3

To view drawing more in detail please click on the picture

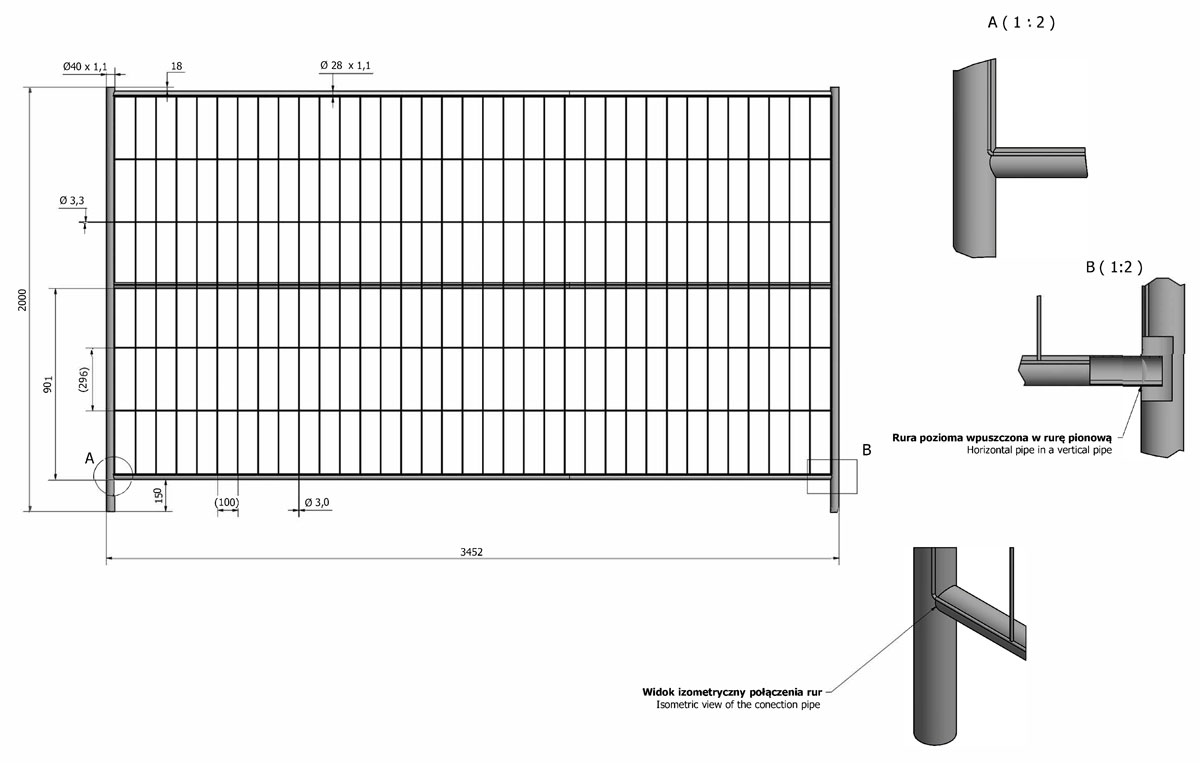

10039 – Mobilzaun business superround

04/18/2020

3,50 x 2,00, mesh welded inside the frame, bottom tube moved in vertical tube, hot dipped galvanized, also available with original hook / eye system and as a cheaper option in galvanized

10038 – Mobilzaun business superround

04/18/2020

Height 1,2 m / length 3,5 m / hot dipped galvanized

To view drawing more in detail please click on the picture

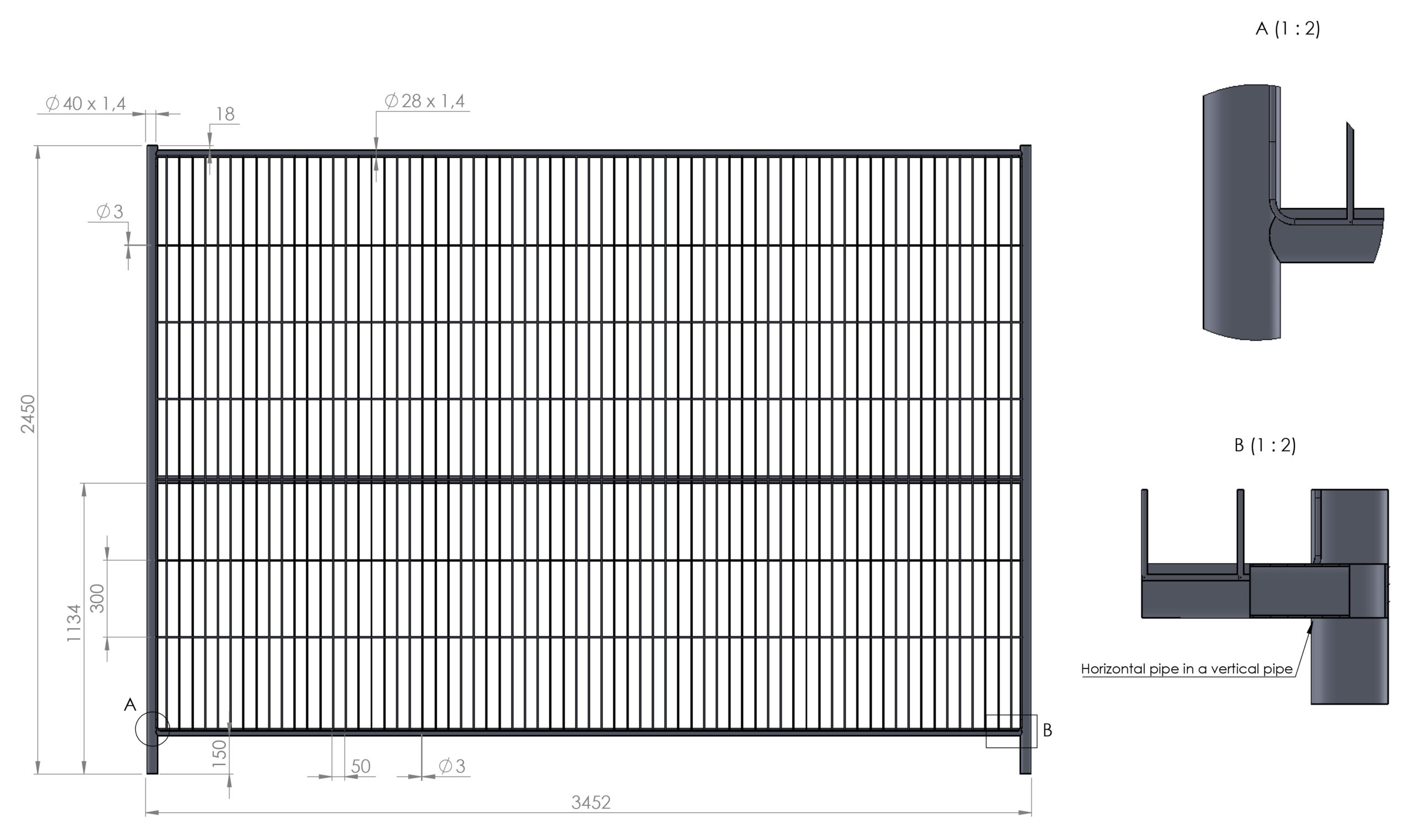

NEW – 10044.2 – Mobile fence exclusive

04/18/2020

Height 2,45 m / mesh 50 x 300 / 3 horizontal tubes, hot dipped galvanized

To view drawing more in detail please click on the picture

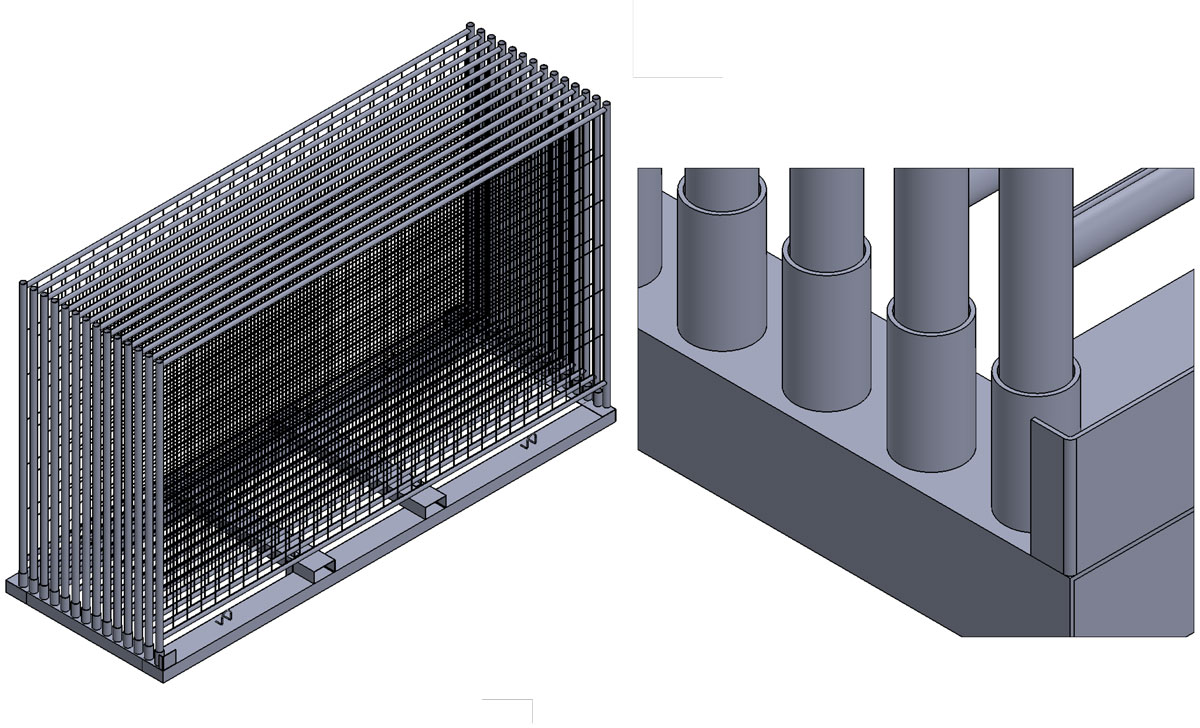

Pallet system „tube in tube“

03/30/2020

We started to build all pallet systems in “tube in tube” system as opposed to “tube on tube”. The big advantage is that the fences with deformations and waste inside the tube can still be used with a pallet.

Concrete barrier 10005.5 – closed panel

03/30/2020

Concrete barrier with 1.000 kg and hoarding panel /

total height 2,5 m

Lockable mobile fence gate

02/16/2019

We present our mobile fence gate, fully usable in all fencing systems, no extra parts, with lock system, knob on one side and pawl on the other.

Individual company advertising

03/06/2018

When ordering 100 panels or more, we offer a special label with personal design , the extra price depends on volume and number of colors.

When ordering over 500 panels, the service is free of charge.

Difference hot dipped galvanized – pre galvanized (sendzimir)

03/01/2018

There is sometimes a misconception when talking about different kinds of surfaces mobile fencing.

Most of the manufacturers use sendzimir tubes and wires. This means that before welding, the material is galvanized with a very thin level of zinc with a thickness of 15 – 20 pm.

After the process of galvanization tubes and wires are cut and these areas are not protected any more and start to rust.

Now, hot dipped galvanized is something different. Here, black tubes and wires are welded and then they go to galvanization plant. There, several chemical processes are done in different bathes, to finish off with the zinc bath in a temperature of 450°. The whole material is submerged and its surface is covered with a minimum of 75 – 80 pm, which is five times more than regularly galvanized material.

Usually people look for a galvanized fence but they do not realize what kind of galvanization is the most beneficial.

Different welding processes

03/02/2018

Most of the mobile fences on the market are welded automatically. It means, that to reduce their costs, manufacturers use pre-galvanized materials. As a consequence, a basic MIG welding process is impossible. So they use an alternative method by pressing the tubes against each other, bringing electricity through the connecting point to a temperature of 400°C so the material should meld together. But many factors can cause poor results of this technique. One of them is oil. You should know that tubes are imported mainly from Asia by sea which is a 30 day journey on salty waters. Oil and fat is applied on the tubes to protect them from salt during the travel to Europe. Unfortunately, this grease used on the tubes may cause faulty work of the electrodes.

So the technique mentioned above is all in all unreliable and unsustainable.

Our process is based on an old MIG welding tradition: a hand welding gun and a wire of welding electrodes that binds the tubes. This technique enables you to see a real welding point as opposed to the previously mentioned one.